Rotary engines, known for their unique design and operation, diverge from the conventional piston engine systems. Introduced by engineer Felix Wankel, these engines employ a spinning rotor instead of reciprocating pistons, offering a different approach to internal combustion. This introduction will delve into the intriguing world of rotary engines, exploring their design, operation, components, and advantages, as well as comparing them with typical engines. The text will also discuss potential drawbacks, applications in modern technology, and the future of this ingenious invention. From fundamentals to futuristic potentials, embark on the exploration of rotary engines.

The Unique Design of Rotary Engines

The structure and design of rotary engines differentiate them from conventional engines. Typically, the rotary engine – also known as a Wankel engine, after its inventor, Felix Wankel – adopts a distinctive shape, being doughnut-like, or more technically, epitrochoidal. Instead of the reciprocating motion visible in most regular engines, the rotary engine operates through a rotating motion. Notably, this rotation occurs inside its housing, which accommodates a rotor that replaces the pistons found in traditional engines.

Another unique trait in the rotary engine’s design is its significantly fewer moving parts, contributing to its compact size and lighter weight. This revolutionary design effectively reduces complexity, friction, and potential mechanical faults while improving engine balance. Consequently, the ingenuity of the rotary engine’s architecture provides a fascinating instance of engineering prowess, marking a noteworthy departure from conventional engine designs.

Understanding the Basic Mechanism of Rotary Engines

In order to understand rotary engines, it’s important to grasp their basic mechanism. Rotary engines function in a dramatically different way than traditional piston engines. The main difference lies in the process of converting pressure into rotating motion. Simply put, they operate through a process wherein the pressure of combustion is captured in a chamber, causing a rotor to move around an output shaft, yielding a rotary motion. These engines have a unique ‘epitrochoid’ shaped housing, within which a triangular rotor orbits.

Unlike classic engines, the rotary engine undertakes all four stages of the combustion cycle in different parts of the housing, simultaneously. The rotor subdivides the working chamber into multiple separate volumes, each of which simultaneously executes a different stage of the cycle. This concise, but constant rotating system allows a rotary engine to run incredibly smoothly and quietly. By truly understanding this basic mechanism, one can fully appreciate the innovative design of rotary engines.

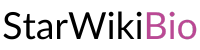

The Components of a Rotary Engine

The rotary engine, unlike conventional engines, has fewer components, resulting in fewer moving parts and a more streamlined operation. The core components of a rotary engine include the rotor, the eccentric shaft on which the rotor operates, the spark plugs that ignite the air-fuel mixture, and the housing that encloses these components. Additionally, the rotary engine also consists of an intake port for the air-fuel mixture to enter, and an exhaust port that serves as an outlet for the burnt gases. The simplicity of these components, in a largely symmetrical design, offers unique advantages that distinguish rotary engines from their piston counterparts – such as low vibrations, high power-to-weight ratio, and a smoother operation. Each component plays a vital role in the operation of the engine, contributing to its unique attributes and overall functionality. You can find out more on Kirill’s page https://yurovskiy-kirill.ru/

The Working Principle of a Rotary Engine: Step by Step

The working principle of a rotary engine follows a unique sequence that sets it apart from traditional engines. The process begins when a mixture of fuel and air is inserted into the combustion chamber as the rotor exposes an intake port. Next, as the rotor continues to turn, it compresses the mixture, making it highly flammable. Then, the spark plug ignites the fuel, causing a mini explosion which further propels the rotor to turn. Hence, the exhaust gases are expelled as the rotor exposes the exhaust port. This is why the rotary engine, unlike the reciprocating cylinders found in piston engines, uses rotation for power production. The rotor continually moves in one direction, thereby ensuring a smoother, less complicated process than traditional machines. This unique operational style is the key distinguishing factor of rotary engines.

The Advantages of Using Rotary Engines

Rotary Engines have several advantages that make them preferable in some applications. Firstly, they have far fewer moving parts than traditional engines, reducing the chances of mechanical failure and simplifying maintenance. This compact design also makes them lighter and smaller, thus saving space. Rotary engines are known for providing smooth, continuous power that avoids the vibrations common in piston engines. They have a high power-to-weight ratio, delivering impressive power despite their small size.

Additionally, this type of engine is less complex, making it easier to understand and repair, which can lower long-term ownership costs. Rotary engines also tolerate high rotational speeds better than other engine types without significant wear and tear. This makes them ideal for high-performance applications, like car racing and aviation, where high RPMs are essential. Therefore, the benefits of rotary engines can significantly outweigh the disadvantages in certain contexts.

Potential Drawbacks of Rotary Engines

Despite the notable advantages, there are some potential drawbacks of rotary engines that we should bear in mind. The main disadvantage lies in the fuel consumption; they’re often harsher on fuel than their piston counterparts due to the constant combustion process. They also produce more emissions, making them less environmentally friendly. Furthermore, the unique design and complicated working mechanism of rotary engines make them challenging to manufacture and repair. The seals between the rotor and the housing also experience a high amount of wear and tear, which can lead to increased maintenance and repair costs. Despite the ingenuity of their design, these downsides often outweigh the benefits for many consumers, leading to limited use of rotary engines in today’s vehicles.

Comparison: Rotary Engines vs. Traditional Engines

In comparing rotary engines to traditional engines, several defining points emerge. The defining characteristic of rotary engines is their compact, lightweight design, which translates into high-power output relative to their size. Unlike the reciprocating motion of pistons in conventional engines, rotary engines operate in a smooth, circular motion, resulting in less vibration. However, traditional engines generally prove to be more fuel-efficient; the unique design of rotary engines leads to higher fuel consumption. Also, traditional engines have a longer lifespan due to the more wear-resistant materials used in their construction. Thus, while rotary engines offer certain benefits such as size and power advantage, traditional engines remain more economical in terms of fuel consumption and durability. It is essential to weigh these attributes based on the specific requirements of their intended applications.

Applications of Rotary Engines in Modern Technology

The versatility and unique attributes of rotary engines allowed them to find considerable applications in modern technology. The most common use is in motor vehicles, particularly sports cars, due to their high power-to-weight ratio. The Mazda RX series is a prime example of this. However, it’s not the only domain where they’re utilized. Rotary engines are also found in motorcycles, aircraft, marine vessels, and even some power generators. Further, due to their compact size and less vibration, they are an attractive option for drones and other small unmanned vehicles. As technology continues to evolve, opportunities for the implementation of the rotary engine in other areas can only increase, proving the worthiness of its somewhat unconventional design and operation. In other words, their application isn’t limited to the internal combustion engine scenario alone; various industries can harness their potential.

The Future of Rotary Engines

The future of rotary engines appears promising despite their present-day limitations. Modern technology continues to evolve, presenting opportunities for overcoming the challenges currently faced. With research ongoing into improving the fuel efficiency and reducing the emissions of these rotary engine types, it is expected that the adoption in the automotive sector will potentially increase. Many believe rotary engines are well-positioned to play a role in the electrically-assisted powertrain of the future due to their light weight, compact size and vibration-free operation. Moreover, noteworthy applications of the rotary engine outside of the automotive world, such as in drones and aircrafts, suggest they still hold untapped potential. Though their progress may be slow, in a world committed to less impact on the environment, the interest in the rotary engine structure offers promising prospects for a more substantial role in the future.